SÄKAPHEN Tube Side Re-lining of Heat Exchangers and Tube Sheet Repair

Protecting Critical Assets in the Chemical Processing and Petrochemical Industries

To ensure economic and ecological use of critical assets used in the chemical processing and petrochemical industries it is vital that process equipment has suitable longevity of performance and service with as little down time as is practicably possible.

Box Coolers which are only externally coated on the shell side can be re-lined by removal of the existing coating by abrasive blasting and then fully re-coated. Pyrolysis is not required in this specific instance.

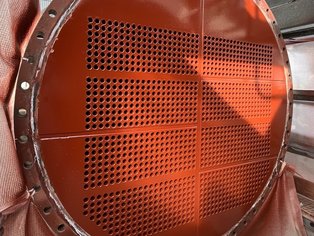

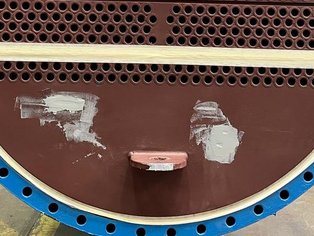

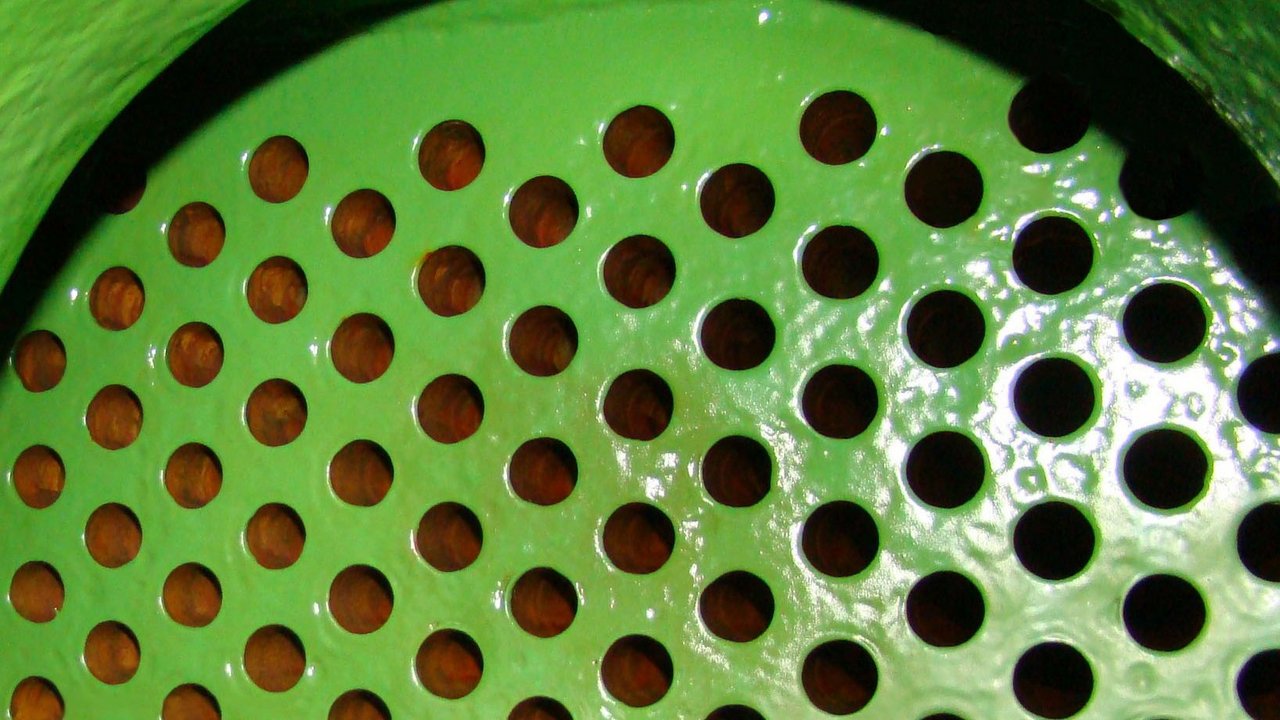

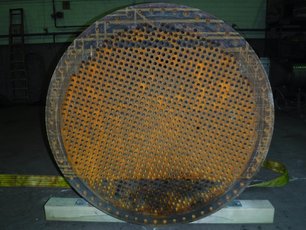

Further localised repairs that allow direct access as in tube sheets, water boxes, channels, channel covers and floating heads can be spot repaired with a suitable SÄKAPHEN Cold Cure Repair Material as determined by the original Heat Cured lining or if desired, fully stripped, re-lined or re-coated.

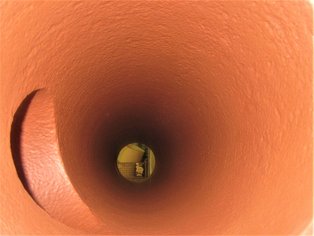

Lining removal and re-lining of heat exchangers is not an issue when using SÄKAPHEN linings applied on the tube side and / or on the tube sheet, especially so when originally lined with SÄKAPHEN. The existing SÄKAPHEN lining can be removed by pyrolysis which is the thermochemical decomposition of organic matter into a solid residual coproduct in an inert environment (i.e. in the absence of oxygen) and then cleaned further by abrasive blasting in accordance with ISO 8501-1:2007 Sa3. SÄKAPHEN lining is then completed as per standard procedures on newly fabricated equipment.

Further typical applications