Coating of Rotating Equipment

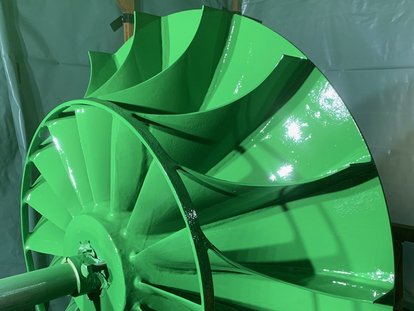

Coating and Re-coating of turbines, impellers and other rotating equipment

SÄKAPHEN are prominently renowned for the supply and application of high-quality linings and coatings as applied to rotating equipment operating in severe and aggressive environments, such as industrial manufacturing, chemical processing, waste incineration and power plants.

Corrosive media ranges from aggressive exhaust gases at high temperatures of 200°C, which when condense form Sulfuric Acid (H2SO4), Hydrogen Sulfide (H2S), Hydrofluoric Acid (HF) and Hydrochloric Acid (HCl) to water saturated with chemicals from exhaust filtration or other process media, i.e. water from the coking process or liquids being recirculated for chemical cleaning.

We offer you a choice from the extensive range of our exceptional products comprising but not limited to Heat Cured Phenolics / Epoxy-Phenolics alongside Cold Cured Epoxies, Novolac Vinyl Esters and Epoxy Vinyl Ester, depending on the type of equipment and operating conditions.

A subsequent advantage of applying SÄKAPHEN linings or coatings to rotating equipment is the formation of a thin, uniform protective layer where minimal additional mass is added to the impeller or turbine therefore reducing potential balancing issue during commissioning and operation. The linings and coatings are not affected by temperature fluctuations and offer temperature resistance up to 200°C and in certain instances, peaks above this depending on the medium. Such is the enhanced adhesion to the substrate the linings or coatings are not affected by high centrifugal forces. Finally, the lining or coating can be easily removed by abrasive blasting should the need arise for Non-Destructive Testing or Examination (NDT / NDE) and the lining or coating can be subsequently repaired or re-lined or re-coated as required.

Coating and Re-coating of turbines, impellers and other rotating equipment

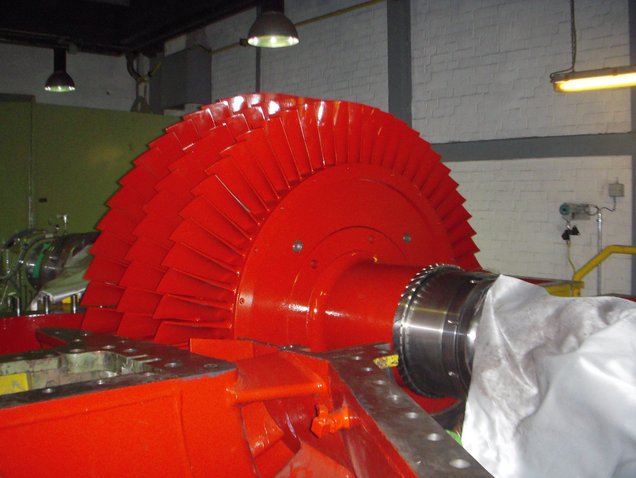

SÄKAPHEN Coating

of Turbines

Corrosion Protection against Fume Condesate, Furnace Gases and other Corrosive Media.

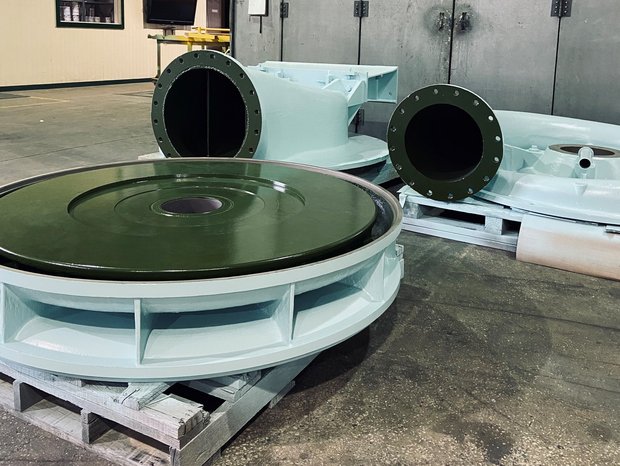

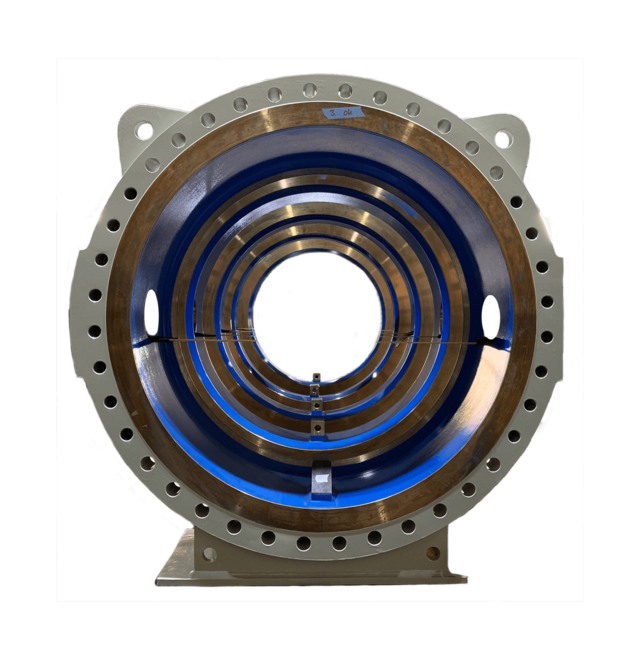

SÄKAPHEN Lining and Coating

of Pump Wheels and Housings

Protection against Corrosion and Incrustation in Severe Operational Conditions.

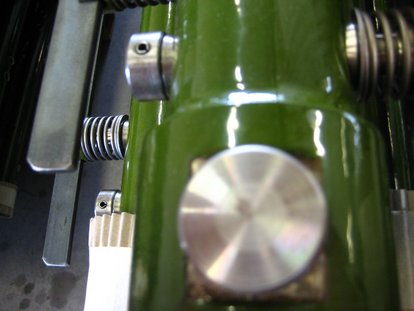

SÄKAPHEN Coating

of Scraped Surface Heat Exchangers

Corrosion Protection and Low Friction Surface on Scraped Surface Heat Exchangers.

SÄKAPHEN

Re-Lining and Re-Coating

Lining and Coating Removal and Re-Lining / Re-Coating for NDT / NDE Integrity