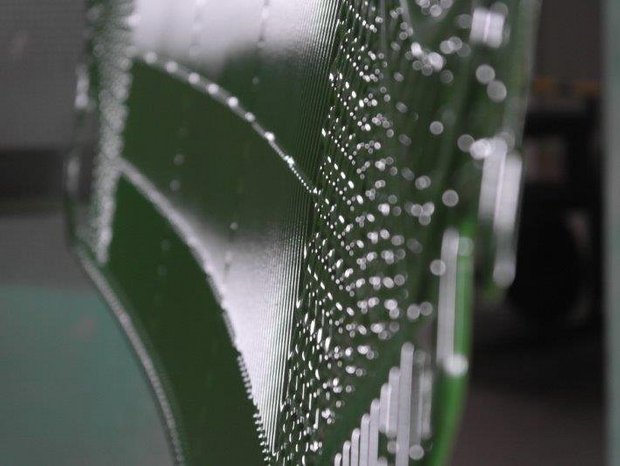

SÄKAPHEN Coating of Plate Heat Exchangers

Protection against Corrosion, Incrustation and Fouling

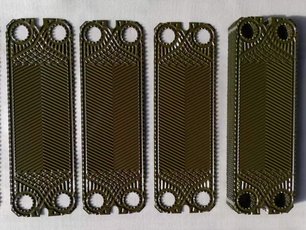

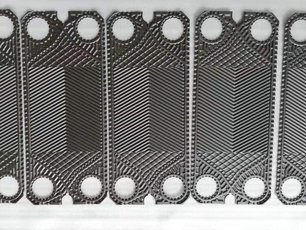

Plate Heat Exchangers have the advantage of offering enhanced heat transfer efficiency and having a comparably larger heat transfer surface combined with a fairly compact and lightweight design. This compact design is achieved by the very small divisions between the plates, which makes this type of cooler difficult to clean and increases the likelihood of clogging caused by incrustation and fouling.

Bringing its expertise from shell and tube heat exchanger linings and coatings as well as air cooler coating, the hydrophobic surface characteristics of the majority of SÄKAPHEN's baked phenolic and epoxy-phenolic range significantly reduces incrustation and fouling, making the surface easy to clean. Its superior chemical resistance further protects from chemical corrosion, such as hydrocarbons, varying qualities of crude oils and acids. This results in heavily reduced downtime and large cost savings due to avoiding or reducing dismantling, cleaning, plate exchange and re-commissioning of the coolers.

The effect of SÄKAPHEN heat cured linings and coatings on the heat transfer rate measured in W/mK is minimal and becomes negligible when being compared to the severe negative impact of incrustation and fouling on heat transfer. Depending on the lining or coating specified, SÄKAPHEN linings and coatings are resistant to cold wall effect.