35+ years in service: SÄKAPHEN Si 14 E protects pipe prover in harsh offshore conditions

Si 14 E

At SÄKAPHEN, we take pride in the longevity and resilience of our high-performance protective coatings and linings. As had already happened some time ago with an epoxy-phenolic product that reached 38 years of service, a recent case from the offshore sector highlighted once again just how enduring our technology can be.

An unusual success case

Last month, an operator in the North Sea (Norway) faced an unusual maintenance issue: their pipe prover—or prover loop,a precision device used to calibrate flow meters in oil and gas production—had accumulated unwanted liquid and sediment after decades of operation. Before starting the cleaning process, the operator needed to confirm the type of internal lining and ensure compatibility with modern cleaning chemicals.

Because remarkably, the lining had been in service for over 35 years without replacement.

Although documentation dated back to 1987–1990, the lining was identified as SÄKAPHEN Si 14 E, one of the most widely applied materials in the industry for meter provers. In the operators’ words: “I assume it is SÄKAPHEN Si 14 E, as that is the industry standard.”

The cleaning phase

The cleaning contractor proposed a two-stage cleaning process at 80 °C, including degreasing and descaling.

SÄKAPHEN’s technical team reviewed the cleaning cycle, analyzed the chemical composition of the detergents, and confirmed that Si 14 E would remain unaffectedby the cleaning process.

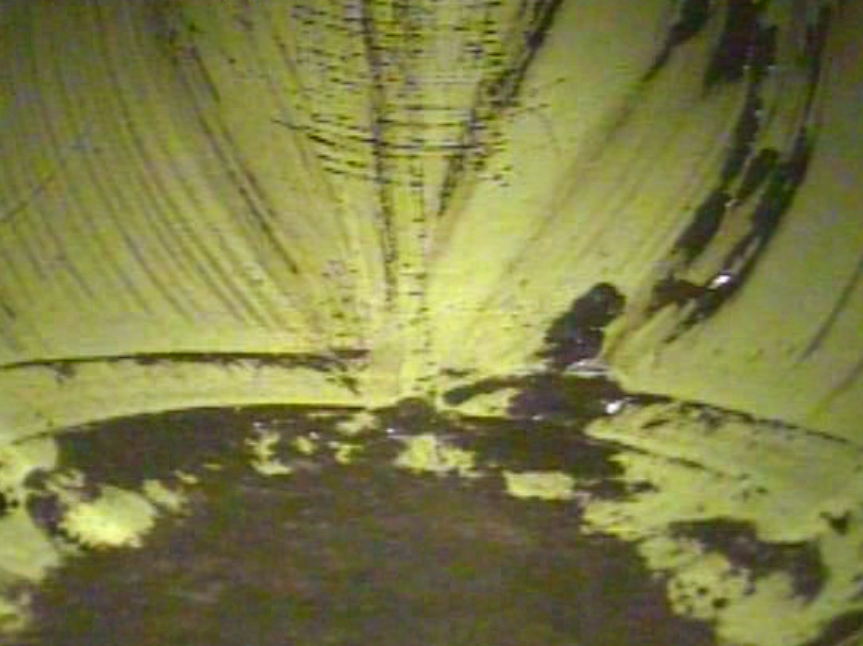

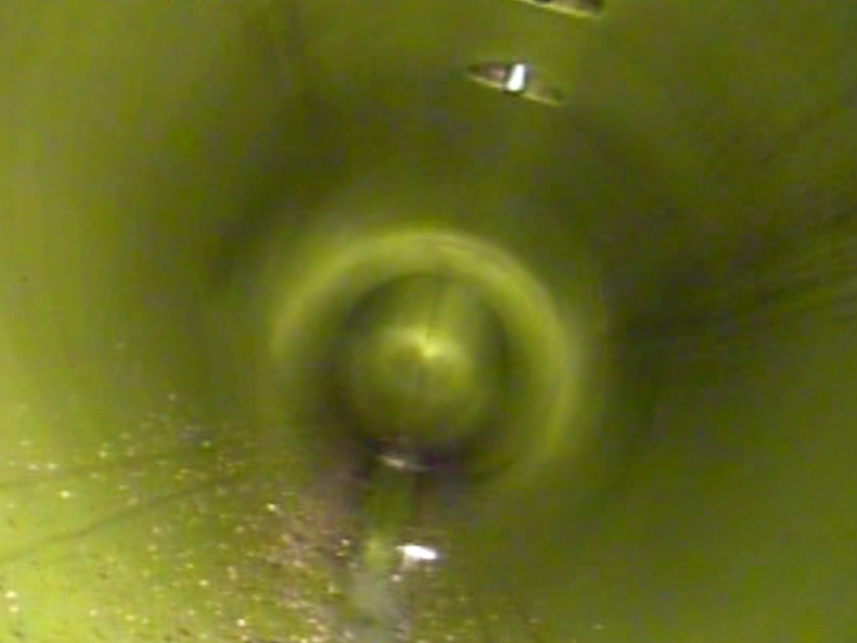

Following 20 hours of cleaning and inspection, the operator reported excellent results. The system was flushed with pressurized water and nitrogen, successfully removing residual mud, sand, and particles.

Why Si 14 E still performs decades later

SÄKAPHEN Si 14 E is a phenolic-based, heat-cured, hydrophobic lining designed for long-term resistance in highly acidic to weak alkaline environments. With a dark green, high-gloss finish, it offers:

- Exceptional chemical resistance to organic and inorganic acids, hydrocarbons, salt solutions, alcohols, fume gases, and cooling water (including brackish, river, sea, and deionized water).

- Superior hydrophobic properties, reducing caking, fouling, and incrustation.

- Durability against temperature fluctuations, maintaining integrity under harsh operating conditions.

- Direct-to-metal application with self-priming and machinable properties after curing.

- Developed for demanding applications such as heat exchangers, condensers, coolers, impellers, desalination plants, ISO tanks, vessels, and meter provers, Si 14 E continues to prove its value decades after installation.

Proven performance

This case study from the North Sea underscores the long-term reliability of SÄKAPHEN linings. Even after more than three decades of continuous offshore service, our Si 14 E delivered the protection required for critical calibration equipment, demonstrating once again that high-quality coatings are an investment in reliability, accuracy, and safety.